Advanced Fasteners and Machining Techniques for Personalized Production

Unveiling the Ins And Outs of Bolts and Machining Processes for Optimal Performance

In the realm of engineering and production, the selection of bolts and the ins and outs of machining procedures play an essential function in determining the ultimate performance and toughness of an item. From the seemingly uncomplicated task of picking the ideal sort of bolt to the complex precision machining strategies used, every action in this procedure needs precise focus to information. As we start this exploration right into the world of fasteners and machining, we will certainly reveal the subtle yet critical variables that can considerably affect the performance and high quality of the final item, clarifying the frequently neglected facets that can make all the difference in attaining optimal performance.

Relevance of Correct Fastener Choice

Selecting the ideal fasteners is important in ensuring the structural stability and longevity of any mechanical setting up. Bolts play an essential duty in holding components together safely, with the ideal choice contributing considerably to the total performance and reliability of the assembly. When choosing bolts, elements such as material compatibility, environmental problems, load-bearing capability, and simplicity of installation have to be meticulously thought about to guarantee optimum efficiency.

Improper bolt option can cause a series of issues, consisting of loosening, corrosion, and even architectural failing. Using fasteners that are not fit to the details requirements of the setting up can jeopardize its functionality and pose safety and security risks. Engineers and developers need to diligently assess the application needs and choose fasteners that meet or surpass the needed standards and requirements.

Furthermore, the right bolt selection process entails evaluating the joint layout, expected loads, vibration degrees, and potential thermal growth or tightening to make sure that the chosen bolts can stand up to the operating conditions properly. By prioritizing correct bolt choice, suppliers can improve the top quality, toughness, and performance of their mechanical assemblies.

Kinds and Characteristics of Fasteners

A necessary aspect of mechanical settings up hinges on comprehending the varied kinds and distinct features of bolts utilized in various industrial applications. Fasteners are critical components that hold frameworks together, making certain stability and capability. There is a vast array of bolts readily available, each designed for details functions based upon the application demands. Typical sorts of bolts consist of screws, screws, nuts, rivets, pins, and washers.

Screws are threaded bolts that are commonly used to join 2 or even more parts with each other. Nuts are internally threaded fasteners that mate with screws to hold components with each other. Washing machines are slim plates that distribute the tons of a fastener, protecting against damages to the product being attached.

Comprehending the attributes of each sort of bolt is essential for picking the best one for a certain application, making certain ideal performance and integrity of the mechanical assembly. Fasteners and Machining.

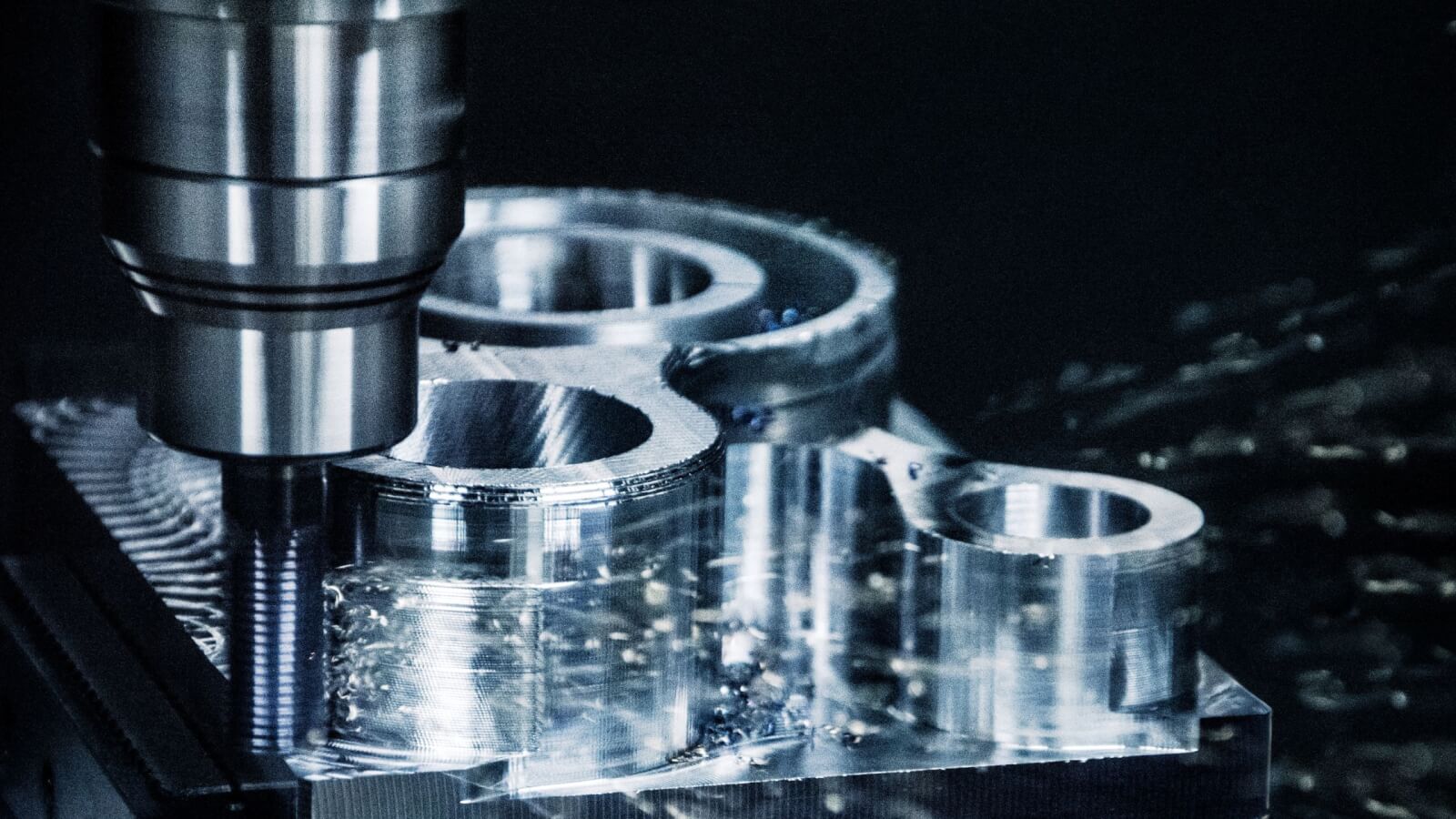

Accuracy Machining Techniques for Efficiency

The complex style demands of numerous fasteners necessitate utilizing accuracy machining methods for ideal performance in producing procedures. Precision machining is essential in making certain that bolts fulfill the precise specs required for their intended application. One of the main methods made use of in accuracy machining is Computer system Numerical Control (CNC) machining, which enables high degrees of precision and repeatability in the manufacturing of bolts. CNC devices are qualified of doing complex cuts and forming operations with very little human treatment, resulting in boosted effectiveness and consistency in the manufacturing process.

By utilizing precision machining strategies, producers can enhance the quality of bolts, reduce product waste, and enhance total production efficiency. The use of sophisticated machining procedures aids make sure that bolts fulfill market standards and customer assumptions for performance and integrity.

Variables Influencing Machining Process Performance

Numerous variables play a significant duty in figuring out the efficiency of machining processes in the production of bolts. The very first essential aspect is the choice of reducing devices. Selecting the proper tools based upon the material being machined, wanted coating, and reducing speeds can substantially affect the efficiency and top quality of the machining procedure. Furthermore, the reducing specifications such as reducing rate, feed rate, and depth of cut are vital variables that affect performance. Fasteners and Machining. Enhancing these specifications based on the particular demands of the fastener being created is essential to attaining economical and precise machining.

Machine rigidness and security additionally play an essential function in identifying machining procedure performance. An experienced driver can make real-time modifications, troubleshoot problems successfully, and ensure that the machining procedure runs efficiently, ultimately impacting the last quality of the bolt.

Quality Control Procedures in Manufacturing

Aspects affecting machining process performance, such get redirected here as cutting tool choice and machine stability, directly effect the implementation of quality assurance actions in production. Quality assurance procedures are essential in guaranteeing that items meet the required specs and standards. In the manufacturing process, numerous methods are utilized to maintain top quality criteria. Inspection and testing play a critical duty in determining any kind of deviations from the wanted end result. Regular upkeep of machining devices is also important to maintain quality control. Calibration of equipments and tools is essential to ensure precise and precise production processes. Additionally, applying standard operating procedures and protocols can aid in maintaining consistency and high quality throughout the assembly line. Quality control gauges not just focus on the end item yet also on every stage of the production procedure to stop errors and flaws. By sticking to pop over here stringent high quality control steps, makers can boost customer fulfillment, build a credibility for dependability, and ultimately accomplish ideal efficiency in their machining procedures.

Final Thought

Finally, picking the best bolts and utilizing accuracy machining strategies are vital for optimum performance in manufacturing procedures. Recognizing the kinds and qualities of bolts, in addition to aspects influencing machining process performance, can lead to boosted performance and high quality control procedures. By paying interest to these intricacies, suppliers can accomplish greater degrees of efficiency and integrity in their items.

In the realm of design and production, the choice of fasteners and the intricacies of machining procedures play a pivotal duty in establishing the utmost efficiency and toughness of a product (Fasteners and Machining). One of the key methods used in accuracy machining is Computer Numerical Control (CNC) machining, which enables high levels of precision and repeatability in the manufacturing of fasteners. The usage of advanced machining processes helps make sure that bolts satisfy sector criteria and client assumptions for efficiency and integrity

In conclusion, selecting the appropriate bolts and making use of accuracy machining strategies are important for optimal performance in manufacturing processes. Understanding the kinds and characteristics of fasteners, along with variables affecting machining procedure efficiency, can lead to these details improved efficiency and top quality control actions.